When it comes to high-pressure air compressors, the choice between a 3-stage and a 4-stage model can significantly impact performance and efficiency. Whether you’re a firefighter, working in demanding industrial environments, or conducting rigorous testing, understanding the difference between these types of compressors is crucial.

In this resource, we will cover:

A multi-stage compressor works by taking ambient air through the air intake. The air then goes through multiple stages of compression. Depending on the compressor, this could be 2, 3, 4, or even 5-stages.

Between each stage, intercoolers remove heat. At the final stage, a moisture separator removes wet air and moisture levels from the air.

The most common types of breathing air compressors are 3-stage or 4-stage compressors.

The final stage compressed air is cooled and moisture is removed.

The final stage compressed air is cooled and moisture is removed.

Compressor stages play a crucial role in the overall performance of the model, increasing the efficiency and performance of the entire breathing air system.

The fundamental function of a multi-stage compressor is to divide the compression process into multiple stages. This results in higher pressure levels (PSI).

The compression is achieved by employing a series of decreasing diameter cylinder stages, and intercoolers that cool the air between each of these stages.

As air is compressed, two things happen:

So, to produce high-quality air, the temperature needs to be lowered and the moisture removed. This is where intercoolers and moisture separators come into play.

Intercoolers are placed between compression stages to reduce the overall temperature. Removing the heat ensures that critical temperatures are not exceeded, which would put strain on the model – shortening its lifespan or causing mechanical failure.

Moisture separators are placed at the final stage, after the intercooler has removed the heat. Moisture separators remove the wet air and moistures from the compressed air. This helps the air meet or exceed rigorous breathing air standards.

A multi-stage compressor offers several benefits and advantages over single-stage compressors.

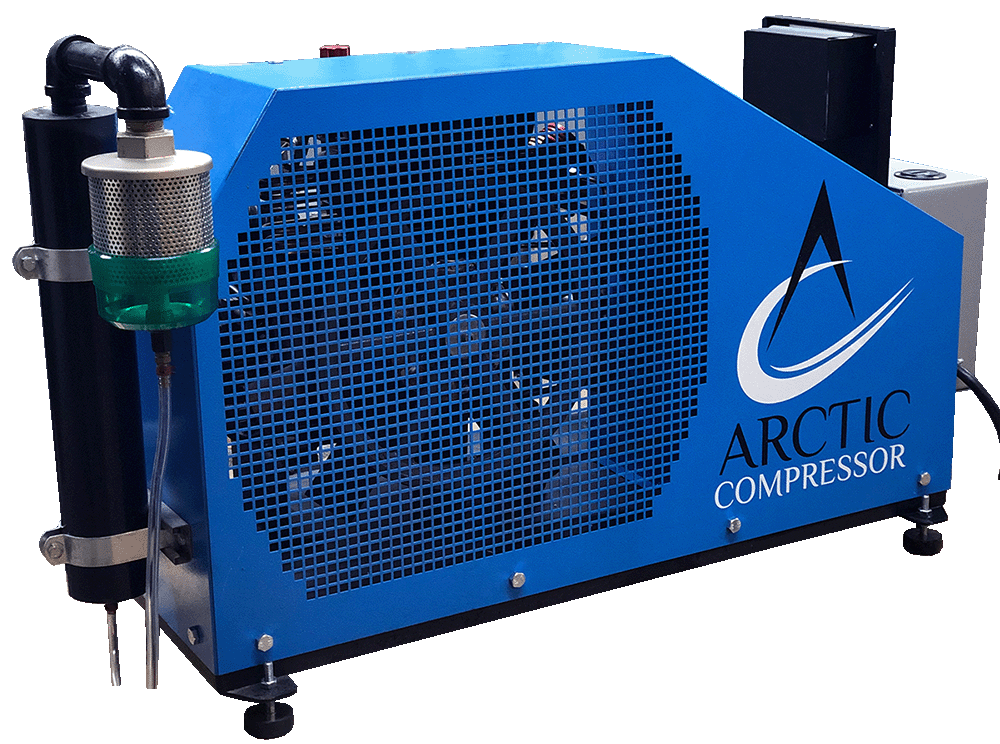

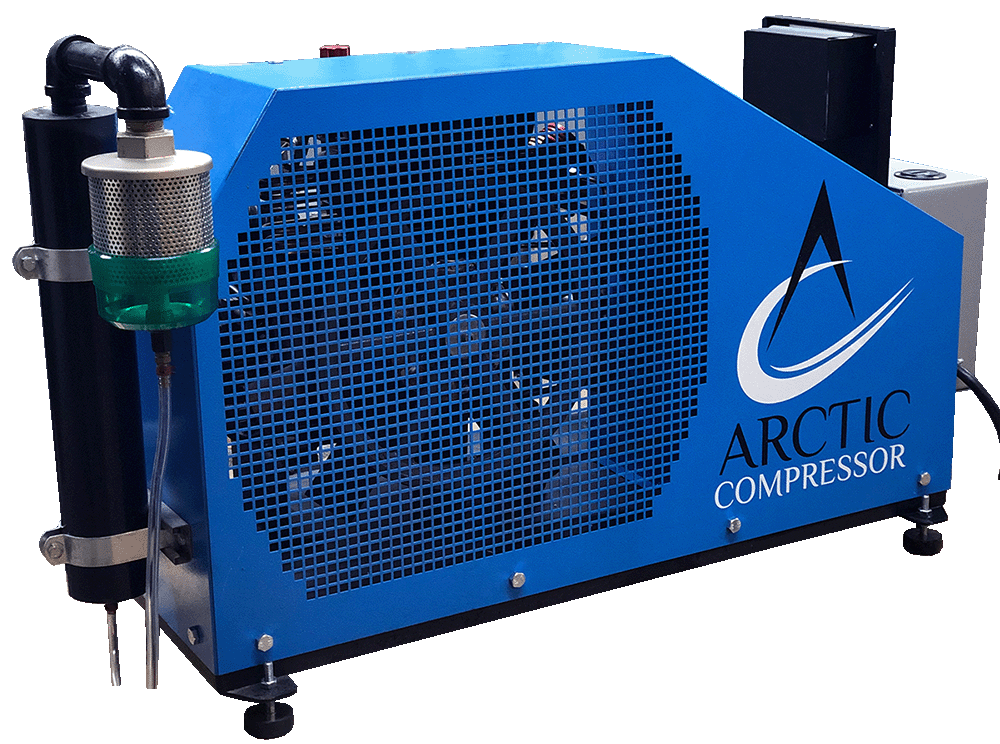

Arctic Compressor offers exceptional breathing air systems for many applications. There are several Arctic Compressor products to consider when evaluating breathing air systems, many of which offer customizations to meet the specific needs of your department or organization.

Intercooling between stages allows for better heat management, reducing the heat before use. This is especially important for breathing air applications.

Multi-stage compressors are designed to achieve higher pressure levels more efficiently than single-stage compressors. While single-stage compressors can theoretically reach high pressures, they would require an impractically large motor and be highly inefficient. More stages allow for better heat dissipation between compression cycles, resulting in more efficient operation, especially at higher pressures.

Some multi-stage compressors reach 7000 PSI, including Arctic Compressor’s enclosed compressors.

By using intercoolers and moisture separators, multi-stage compressors remove moisture from the air, allowing the purification systems to produce high-quality, breathing-grade air.

3-stage air compressors are commonly used for fire departments, industrial pressure testing, SCUBA diving, paintball, and PCP air rifles. Well suited for most small and medium air volume applications, 3-stage compressors are a popular choice.

8 - 9 CFM

5000 - 6000 PSI

76 dB

24,000 - 57,000 Cu. Ft.

7.5 HP

8 - 9 CFM

5000 - 6000 PSI

92 dB

9,800 - 24,000 Cu. Ft.

7.5 - 10 HP

Longer continuous run times and larger volumes of high-pressure air would be much better suited with a 4-stage compressor. These units are often used for medium or large fire stations, industrial applications, or medium to large dive teams.

4-stage compressors are more energy efficient than 3-stage compressors With the same energy input, a 4-stage compressor will produce more compressed air than a 3-stage compressor.

However, 4-stage compressors are more mechanically complex than 3-stage compressors. They have an additional stage, which involves more components and parts.

Most Powerful

18 - 24 CFM

6000 PSI

83dB

57,000 - 90,000 Cu. Ft.

15 - 20 HP

9 - 14 CFM

6000 PSI

76 dB

24,000 - 57,000 Cu. Ft.

7.5 - 10 HP

9 - 14 CFM

6000 PSI

92 dB

9,800 - 24,000 Cu. Ft.

7.5 - 10 HP

When choosing high-pressure air equipment, it’s important to consider the reliability and quality of what you’re purchasing.

Known for reliability and Truly American-Made™ equipment, Arctic Compressor offers 3 and 4-stage high-pressure compressors to fit your needs.

Ranging from the powerful 2500 Enclosed Series Compressor (4-stage) to our 1000 Open Frame Series Compressor (3-stage), we offer a compressor at a price point that works for you, without compromising quality.

Lead time commonly refers to the time it takes from placing an order to the time the unit is delivered and installed.

On average, most high-pressure air compressors have a several month lead time. However, at Arctic Compressor, our lead time is 9 times faster than our competitors. We are able to offer these fast turnaround times from our Truly American-Made™ values – we have complete control of our manufacturing – all of which is conducted in the United States at our headquarters in Superior, WI.

The trade-off between 3 and 4-stage compressors is one of mechanical complexity vs energy efficiency.

A 3-stage compressor is less mechanically complex than a 4-stage compressor. However, given the same energy input, the 3-stage compressor will output less compressed air than the equivalent-sized 4-stage compressor. With the additional efficiencies, 4-stage systems also operate comparatively cooler.

“I needed something that was going to be able to service our community best. And we found that in Arctic.” Chief Watson

At Arctic Compressor, we specialize in engineering and manufacturing high-quality, reliable breathing air compressors, including systems specifically designed for SCBA applications. Our compressors are built with durability, performance, and safety in mind, backed by exceptional customer support.

Get in touch with our team so we can help you find the best fit for your needs.

Phone:

Copyright 2025 – Arctic Compressor “The simple Choice”. All rights Reserved