High-pressure industrial air compressors intake ambient air and compress it to pressures as high as 6000 pounds per square inch (PSI) for breathing air and other applications. As the air moves through the multiple stages of compression it is cooled after each stage. This cooling is required to make compression to these high pressures possible. High pressure industrial air compressor models can range from 2000 PSI to 6000 PSI.

High-pressure air compressors are used in a variety of applications including fire, industrial, SCUBA, and paintball markets. Things to consider when buying an air compressor include cost, space requirements, and type of usage.

When you need a High-pressure air compressor that will meet SCBA regulations, and fit your budget, Arctic Compressors has a line of products that will meet your compressed air needs. Through our authorized distributor network, we sell and provide service throughout the United States and parts of Canada.

Here’s what we’ll cover:

Click on any of the topics to jump to that section.

- How high is “High Pressure”

- What is breathing air

- What a standard high-pressure compressor system looks like

- Applications for industrial high-pressure compressors

- Open Frame high-pressure air compressors

- 4500 psi air compressors, 5000 psi compressor, 6000 psi air compressors

- What is a cascade filling system

- High-pressure compressor costs

- Maintenance of high-pressure compressors

How high is “high pressure”

High pressure is technically anything compressed to over 150 pounds per square inch (PSI). A standard garage compressor can produce up to that much pressure. While 150 PSI is the starting point of high pressure, Arctic Compressor typically supplies solutions for point of use pressures from 1000 – 6000 PSI. Ask us about your specific applications, and your specific required pressures. Just like with lower pressure compressors, high pressure air compressors usually have high-pressure storage cylinders that are then down-regulated to the final use pressure for the application. This helps reduce short-cycling of the compresor and allows for short bursts of high volume usage.

What is “breathing air”

Breathing air is compressed atmospheric air. Unlike Nitrox or other formulated air types, compressed breathing air is not enriched in any way. It is only purified atmospheric air. With the correct purification system breathing air can meet all the standards required for diving as well as firefighting and safety applications. The quality of compressed breathing air is highly dependent on the surroundings of the compressor or where the intake air comes from.

Our compressors produce high quality breathing air that meets the standards of NFPA 1989 and CGA Grade E. The expandable built in filtration allows you to extend the time between filter change-outs while ensuring that your air is as clean as you need it to be. Our optional electronic Carbon Monoxide (CO) monitors provide continuous monitoring and peace of mind for the machine operators.

What a standard high-pressure compressor system looks like

A standard high-pressure compressor system for use in breathing air and SCBA / SCUBA filling consists of a compressor, storage cylinder, and a containment fill station. Generally, the compressor and storage cylinders used to fill secondary tanks/canisters is designed to produce at least a little bit higher pressure than the final fill pressure. This is due to the nature of filling from a cascade system. For example, most compressors that we sell for breathing air systems are rated for 6000 PSI. This allows easy filling of 2216, 3000, 4500, and 5500 PSI cylinders by simply adjusting the output pressure regulator. Most fill stations are supplied by a cascade storage system or set of storage bottles rather than direct filling from the compressor. The fill station often has an integrated cascade control panel, like the one shown above.

For industrial applications, a single high-pressure compressor that is run while needed may be all that is necessary.

Applications for industrial high-pressure compressors

There are a variety of uses for industrial high-pressure compressors, here are a few.

Breathing Air Applications:

SCUBA tanks used in diving are generally filled to 3000 PSI but tend to be larger tanks. SCBA air packs used in the fire, hazmat, and industry are commonly available at 2216, 4500, and 5500 PSI but are smaller, lighter, and easier to carry in confined spaces.

Industrial HP Air Applications:

The range of industrial uses for high-pressure air is gigantic. A few of the more common applications are listed below.

- Valve testing

- Blow molding

- Leak testing of hydraulic and pneumatic systems

- Lower cost replacement for high pressure nitrogen

- Air blast circuit breakers

- Proof and leak testing of refrigeration heat exchangers

Open Frame high-pressure air compressors

An open-frame compressor has all the necessary features and none of the frills. In general, the unit will have a base and frame, with open sides and front. Within the frame, you have the motor (electric, diesel, or gas) the compressor block, a small filtration system and the drain for the moisture separators. Open frame compressors have a slightly larger footprint as they are normally a side by side motor and block build. Additional filtration can be wall or stand-mounted if desired.

Types of open-frame Compressors available

Arctic 1000 Series Open Frame Compressor

- Air cooled

- 3 stage Arctic Block

- Relief valves on all stages

- Aluminum intercoolers

Enclosed/ Silenced high-pressure air compressors

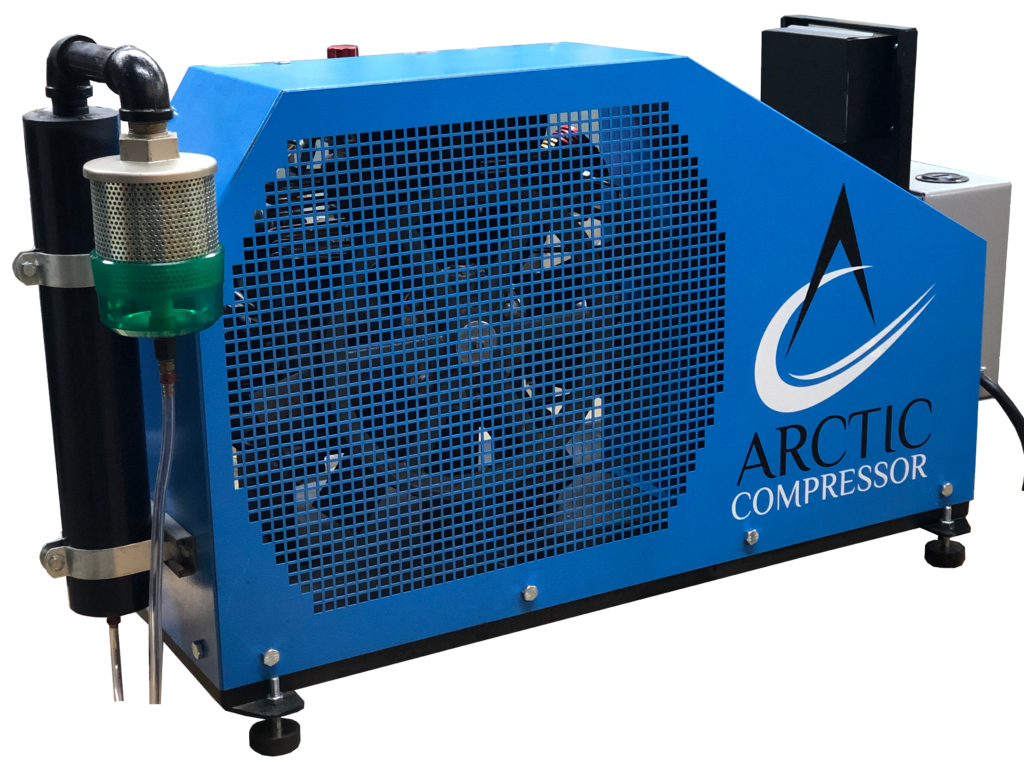

An enclosed frame compressor offers the functionality of the open frame compressor in a nicer looking, smaller footprint. Built in a block over motor configuration these models take up less floor space and are enclosed in a sound dampening cabinet. Outfitted with a vibration reduction system these compressors are well suited for use in manned shops where noise and vibration are a concern. The availability of additional features such as a built-in electronic CO monitor and larger standard internal filtration wrap everything you need into one functional design.

Types of enclosed compressors available

Arctic 1000 Series Enclosed Compressor

- Air Cooled with a High Velocity, 10 Bladed Fan

- Relief Valves on All Stages

- Aluminium Inter Coolers

- Stainless Steel After Cooler

- Interstage and Final Moisture Separators

Arctic 1500 Series Enclosed Compressor

- 4 Stage Arctic Compressor Block featuring:

- Air Cooled with a High Velocity, 10 Bladed Fan

- Relief Valves on All Stages

- Aluminum Inter Coolers

4500 PSI air compressors, 5000 PSI compressors, 6000 PSI compressors

The PSI configuration of your industrial compressor depends on your needs. At Arctic Compressor, we manufacture compressors that produce up to 6000 PSI. Our Standard compressor models produce 5000 PSI and 6000 PSI and are usually used to fill fire department 4500 PSI and 5500 PSI SCBA air packs. We can also set the compressors to produce lower pressure air as needed such as the 2400 PSI or 4500 PSI.

What does “Cascade Filling” mean

A cascade filling system is a bank of large high pressure storage bottles that are filled by the attached compressor. The bottles are set up so the operator can fill bottles in the fill station without the compressor running as they stand there. Filling the storage bottles ahead of time allows there to be a large quantity of compressed air ready to go when it is needed.

The Cascade specific technique is that the operator opens up one storage cylinder at a time, allows the pressure to equalize, and closes the storage cylinder valve. Moving down the line the operator repeats the process, increasing the air pack/bottle pressure one step at a time.

This is more efficient than bulk filling as it extends the number of higher pressure fills from the storage system before the compressor must be turned on.

High-pressure compressor costs

There are many factors that affect the cost of a High-Pressure compressor. In the market, there is a wide range of price points as well as a range of functionality. The cost of a High-Pressure compressor depends on your needs, such as:

- What pressure do you need?

- What volume of output (CFM) do you need?

- Is noise a factor?

- How much space do you have available?

- Do you need a 3 or 4 stage compressor?

At Arctic Compressor we are able to provide a great value to our customers at a competitive price point without sacrificing any of the key functions of the equipment. Our Compressors, Fill stations and business are built on the model of being “The Simple Choice”. Our equipment is simple to install, operate, and maintain. By eliminating many of the complexities from the operation of our compressors, we enable you to get the job done and move on.

Maintenance of a High-Pressure Compressor

We work through an authorized distributor network for sales and service to ensure that experienced technicians are close enough to be convenient for you. They are trained by us and able to perform all installations, routine maintenance, and repair service on our equipment. If you choose to perform your own routine maintenance the list is short and sweet: Air filter change outs, simple oil changes, and check the drive belt tension are all that’s needed up to 500 hours of operation.

Why choose Arctic Compressor

Aside from the value that we provide our customers, we also pride ourselves on customer service. We are easy to get a hold of and can help you with any questions you may have before, during, or after your compressor purchase. If you need anything, let us know!

Who We Are

Arctic Compressor LLC produces a line of High-Pressure Air compressors and Containment Fill Stations for use in the fire safety, industrial, and recreational markets. We have been designing and building high-pressure compressors for more than 30 years.